Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers are used mostly in the chemical processing industry for heating, cooling, condensing, and evaporating highly corrosive liquids and gases. Shell and tube heat exchangers are one of the most popular heat exchanger types of heat exchanger because of their flexibility to accommodate a wide range of temperatures and pressures.

Unlike conventional shell and tube heat exchangers , Niche products avoid scaling and fouling by using tubing made from essentially chemically inert fluoropolymers. Niche is the original fluoropolymer heat exchangers manufacturer and still the only company that makes FEP and PFA tubing for shell and tube heat exchangers types.

These unique materials have advantages overheat exchangers made with metal, graphite or glass. Metal corrodes when it interacts with harsh chemicals, causing maintenance and reliability problems, and may lead to failure under pressure. Graphite and glass tubes may crack from thermal and mechanical shock, which may result in catastrophic failure and costly downtime.

Niche heat exchangers feature braided tubing bundles and unique fused ends that provide significantly better heat transfer from a smaller footprint than similar heat exchangers, allowing installation in virtually any type of tank configuration. Niche proprietary honeycomb process ensures long service life with no leaks or thermo-mechanical failures commonly found on other heat exchangers.

Heat Exchangers Types

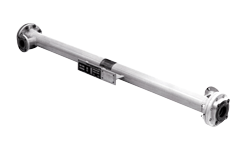

PV-4 Series 3” Shell

Small, inexpensive heat exchangers with three-inch shells, ideal for low flow processes. Keep Reading

30-Series Mid-Size 4” Shell

Medium-size heat exchangers with 4-inch diameter shells, suitable for typical applications. Keep Reading

30-Series Model 218, 525 and 1000

Large heat exchangers with 10-inch diameter shells, designed for large volume processes. Keep Reading

900-Series Large Capacity

Niche largest heat exchangers with 14-inch diameter shells, providing high flow capacity and low pressure drop. Keep Reading

PV-4 Series 3” Shell

PV4 Series Shell and Tube Heat Exchangers (3 inch Shell), are Small (up to 6 feet in length), affordable heat exchangers suitable for low flow applications. Their design maximizes the heat transfer performance of FEP or PFA, as well as “Q” Series fluoropolymer tubing.

- High thermal efficiency

- Corrosion-resistant fluoropolymer construction

- Unique bundle & baffle system

- FEP, PFA or "Q" Series tubing

- CPVC shell material

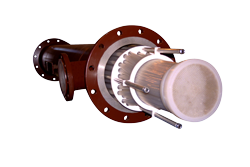

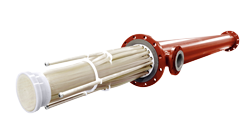

30-Series Mid-Size 4” Shell

Shell-and-Tube Heat Exchangers 30-Series Mid-Size (4 inch shell), In lengths up to 11 feet, this series uses a single-pass, typically counter-current flow design. Tube bundles are joined together to create honeycomb tube sheets. Heads are fluoropolymer-lined, and the flexible tube bundle is easily removable for maintenance. Carbon steel shells are standard; other shell material is available on request. Metal shells are ASME coded and feature TEMA/ANSI end nozzle connections.

- High thermal efficiency

- Corrosion-resistant construction

- Unique seal system

- FEP or Q-Series tubing

- Carbon steel shells standard (others available upon request)

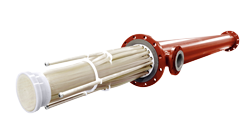

30-Series Model 218, 525 and 1000

Shell and Tube Heat Exchangers 30-Series Model 218, 525 and 1000, are Single pass, typically countercurrent-flow units designed for heating, cooling and condensing. Flexible fluoropolymer tube bundles are joined together to form unique honeycomb tube sheets that add physical robustness.

Material choices include FEP or Q-Series tubing with PTFE-lined heads. Standard shell construction is carbon steel, with other shell materials available on request. Products are ASME coded and equipped with TEMA/ANSI end nozzle connections.

The difference between models 218, 525 and 1000 are the number of tubes per bundle, which increases the heat transfer area. Users should select the model that is right for the application based on length (2 to 24 feet) and heat transfer required.

- High thermal efficiency

- Corrosion-resistant construction

- Unique seal system

- FEP or Q-Series tubing

- Carbon steel shells standard (others available upon request)

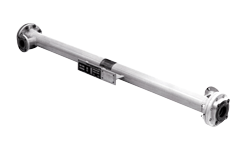

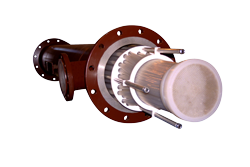

900-Series Large Capacity

Niche's largest heat exchangers, Shell & Tube Heat Exchangers 30 Series Large Capacity Model 900, have 14-inch diameter shells and many fluoropolymer tubes, providing high flow capacity and low pressure drop. Shells are available in a variety of materials, including carbon steel, fluoropolymer-lined carbon steel, and stainless steel. Tube lengths available up to 24 feet.

- High flow capacity

- Low pressure drop

- Unmatched corrosion resistance

- FEP and PFA series tubing

- Variety of shell material